Choosing the right hydraulic fluid for RV slides is critical for smooth operation and long-term reliability. Using the wrong type can lead to leaks, sluggish movement, or even system failure. This guide covers everything you need to know—from fluid types to maintenance tips—so your RV slides work flawlessly every time.

In This Article

- 1 Key Takeaways

- 2 📑 Table of Contents

- 3 What Kind of Hydraulic Fluid for RV Slides? A Complete Guide

- 4 Understanding RV Slide-Out Hydraulic Systems

- 5 Types of Hydraulic Fluids: Which One Is Right for Your RV?

- 6 How to Check and Add Hydraulic Fluid to Your RV Slides

- 7 Maintaining Your RV’s Hydraulic Slide System

- 8 Troubleshooting Common Hydraulic Slide Issues

- 9 Conclusion: Keep Your Slides Smooth with the Right Fluid

- 10 Frequently Asked Questions

- 10.1 Can I use ATF in my RV slide system?

- 10.2 How often should I check the hydraulic fluid level?

- 10.3 What happens if I use the wrong hydraulic fluid?

- 10.4 Can I mix different types of hydraulic fluid?

- 10.5 Is synthetic hydraulic fluid better for RV slides?

- 10.6 How do I know if my hydraulic fluid is contaminated?

Key Takeaways

- Use ISO 32 hydraulic fluid for most RV slide systems: This lightweight, low-viscosity fluid is ideal for the cold starts and smooth operation required in RV applications.

- Check your owner’s manual first: Always consult your RV manufacturer’s recommendations before adding or replacing hydraulic fluid.

- Avoid automotive transmission fluids: While tempting, ATF or motor oil can damage seals and reduce system efficiency over time.

- Look for anti-wear and anti-foam additives: These help protect internal components and prevent air bubbles that can cause jerky slide movement.

- Maintain proper fluid levels and inspect for leaks regularly: Low fluid or contamination can lead to costly repairs and unsafe operation.

- Use only clean, sealed containers when adding fluid: Dirt or moisture in the fluid can clog valves and damage pumps.

- Consider synthetic hydraulic fluids in extreme climates: They offer better performance in very hot or cold environments.

📑 Table of Contents

- What Kind of Hydraulic Fluid for RV Slides? A Complete Guide

- Understanding RV Slide-Out Hydraulic Systems

- Types of Hydraulic Fluids: Which One Is Right for Your RV?

- How to Check and Add Hydraulic Fluid to Your RV Slides

- Maintaining Your RV’s Hydraulic Slide System

- Troubleshooting Common Hydraulic Slide Issues

- Conclusion: Keep Your Slides Smooth with the Right Fluid

What Kind of Hydraulic Fluid for RV Slides? A Complete Guide

If you’ve ever been on the road in your RV and heard a groan, a stutter, or worse—a complete refusal to extend or retract your slide-out—then you know how frustrating it can be. One of the most common causes? The wrong hydraulic fluid. It might seem like a small detail, but choosing the correct hydraulic fluid for RV slides is essential for smooth, reliable operation and long-term system health.

RV slide-outs rely on hydraulic systems to move heavy sections of your rig in and out with precision. These systems use fluid under pressure to power hydraulic cylinders that push or pull the slide. Just like your car’s brakes or steering, the fluid must meet specific standards to work properly. Using the wrong type can lead to poor performance, leaks, seal damage, or even total system failure. And let’s be honest—nobody wants to be stuck with a slide that won’t budge in the middle of a camping trip.

In this guide, we’ll walk you through everything you need to know about hydraulic fluid for RV slides. From understanding fluid types and viscosity to maintenance tips and common mistakes, you’ll be equipped to keep your slides running like new. Whether you’re a full-time RVer or a weekend warrior, this information will help you avoid headaches and enjoy more time on the road.

Understanding RV Slide-Out Hydraulic Systems

Visual guide about What Kind of Hydraulic Fluid for Rv Slides

Image source: gocarlife.com

Before diving into fluid types, it helps to understand how RV slide-out systems actually work. Most modern RVs use hydraulic systems because they’re powerful, reliable, and can handle the heavy loads of large slide-outs. These systems consist of a hydraulic pump, fluid reservoir, hoses, valves, and hydraulic cylinders that do the actual lifting and moving.

When you press the button to extend your slide, the pump pushes hydraulic fluid through the hoses into the cylinders. This pressurized fluid forces the pistons inside the cylinders to move, which in turn pushes the slide outward. To retract, the process reverses—fluid is redirected back to the reservoir, allowing the slide to move back into place.

Because these systems operate under high pressure and involve moving parts, the hydraulic fluid must do more than just transfer force. It also lubricates internal components, prevents corrosion, resists foaming, and maintains stability across a range of temperatures. That’s why using the right fluid isn’t just a suggestion—it’s a necessity.

How Hydraulic Fluid Powers Your Slide

Think of hydraulic fluid as the lifeblood of your slide system. Without it, nothing moves. The fluid must be incompressible so it can transmit force efficiently from the pump to the cylinders. If the fluid were compressible—like air—the system would feel spongy and unresponsive.

Additionally, the fluid must maintain consistent viscosity (thickness) across different temperatures. In cold weather, some fluids thicken and flow slowly, causing sluggish slide movement. In hot weather, they can become too thin, reducing their ability to lubricate and seal properly. That’s why most RV manufacturers recommend a specific grade of hydraulic fluid that performs well in a wide temperature range.

Common Components That Depend on Proper Fluid

Several parts of your hydraulic system rely on clean, correct fluid to function:

– Hydraulic Pump: Generates pressure to move the fluid. Dirty or incorrect fluid can cause wear and overheating.

– Reservoir: Stores the fluid and allows air bubbles to escape. Must be kept at the proper level.

– Hoses and Seals: Made of rubber or synthetic materials that can degrade if exposed to incompatible fluids.

– Control Valves: Direct fluid flow. Contamination or wrong viscosity can cause them to stick or leak.

– Cylinders: Contain pistons that move the slide. Need proper lubrication to avoid scoring or seizing.

Using the wrong fluid can damage any of these components, leading to expensive repairs or even complete system replacement.

Types of Hydraulic Fluids: Which One Is Right for Your RV?

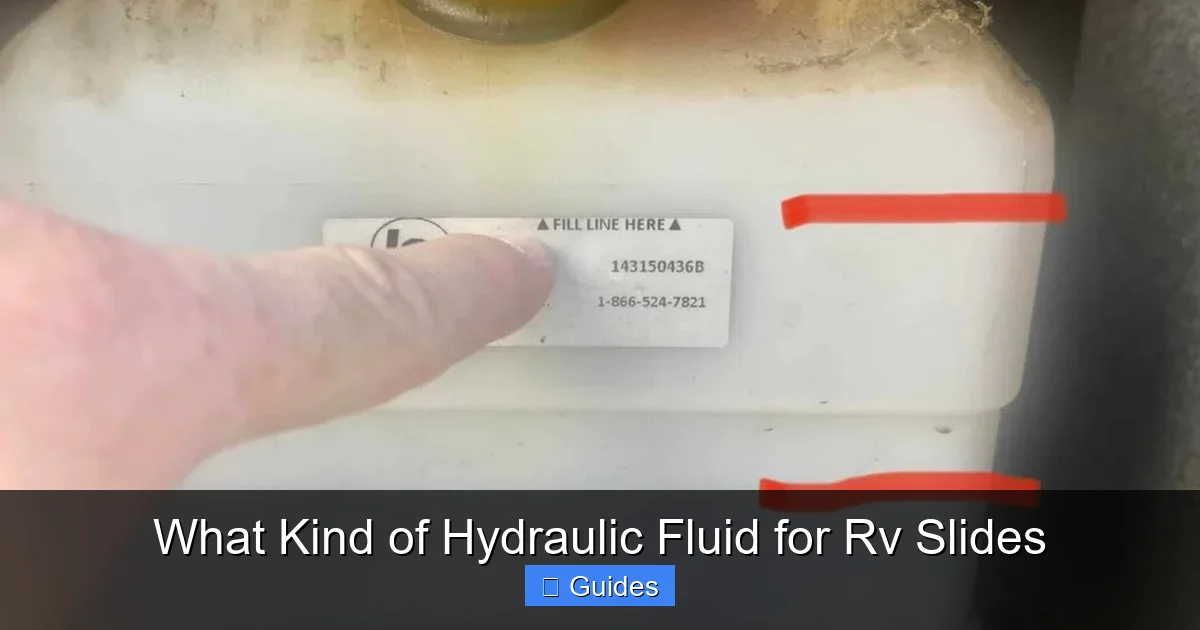

Visual guide about What Kind of Hydraulic Fluid for Rv Slides

Image source: shootingstar-rvresort.com

Not all hydraulic fluids are created equal. In fact, using the wrong type is one of the top mistakes RV owners make. Let’s break down the most common types of hydraulic fluids and which ones are best suited for RV slide systems.

ISO 32 Hydraulic Fluid (Recommended)

The most widely recommended hydraulic fluid for RV slides is ISO 32 hydraulic fluid. This is a lightweight, low-viscosity fluid with a viscosity grade of 32 centistokes at 40°C. It’s specifically designed for systems that require smooth operation at low temperatures and high efficiency.

Why ISO 32? Because it flows easily in cold weather, resists foaming, and provides excellent lubrication for pumps and cylinders. Most RV manufacturers—such as Lippert, Power Gear, and HWH—specify ISO 32 in their owner’s manuals. It’s also widely available at RV supply stores, auto parts retailers, and online.

For example, if you own a fifth wheel with a Lippert slide system, the manual will likely say: “Use only ISO 32 hydraulic fluid. Do not substitute with motor oil or ATF.” Following this advice ensures your system runs smoothly and stays under warranty.

ISO 46 Hydraulic Fluid (Less Common)

Some older or heavy-duty RV systems may use ISO 46 hydraulic fluid, which is slightly thicker than ISO 32. It’s more common in industrial applications or systems that operate in warmer climates. However, in most modern RVs, ISO 32 is preferred because it offers better cold-weather performance.

If your RV uses ISO 46, don’t panic—just make sure you stick with it. Switching to a thinner fluid like ISO 32 could reduce system pressure and cause leaks. Always check your manual or contact the manufacturer to confirm.

Synthetic Hydraulic Fluids (For Extreme Conditions)

If you frequently travel in very cold or very hot climates, consider using a synthetic hydraulic fluid. These fluids are engineered to maintain stable viscosity across a wider temperature range than conventional mineral-based oils.

For instance, if you’re winter camping in Montana or summer boondocking in Arizona, synthetic fluids can prevent thickening in the cold or thinning in the heat. They also tend to last longer and resist oxidation better. However, they’re more expensive, so weigh the cost against your travel habits.

Popular synthetic options include Mobil SHC 500 series or Shell Tellus S4 ME. Just make sure they meet ISO 32 or 46 specifications and are compatible with your system’s seals.

What NOT to Use: Common Mistakes

It’s tempting to use what’s on hand—especially if you’re in a pinch. But avoid these common substitutes:

– Automatic Transmission Fluid (ATF): While ATF is a type of hydraulic fluid, it’s formulated for transmission systems, not slide-outs. It can cause seal swelling, foaming, and reduced lubrication in RV hydraulic systems.

– Motor Oil (10W-30, 5W-20, etc.): Motor oil is too thick and lacks the anti-wear additives needed for hydraulic pumps. It can also damage rubber seals over time.

– Power Steering Fluid: Similar to ATF, it’s not designed for high-pressure slide systems and may not provide adequate protection.

– Generic “Hydraulic Oil” Without ISO Rating: Always check the label. If it doesn’t specify ISO 32 or 46, it may not be suitable.

Using the wrong fluid might seem like a quick fix, but it can lead to costly repairs down the road. Stick to manufacturer-recommended fluids.

How to Check and Add Hydraulic Fluid to Your RV Slides

Visual guide about What Kind of Hydraulic Fluid for Rv Slides

Image source: thecampingadvisor.com

Maintaining proper fluid levels is just as important as using the right type. Low fluid can cause air to enter the system, leading to spongy operation, jerky movement, or complete failure. Here’s how to check and top off your hydraulic fluid safely.

Step 1: Locate the Hydraulic Reservoir

The reservoir is usually found near the hydraulic pump, often under a panel in the storage compartment or near the slide mechanism. It’s a small tank with a cap labeled “Hydraulic Fluid” or “Reservoir.” Some models have a sight glass or dipstick to check levels.

If you’re unsure, consult your owner’s manual or look for a label near the pump. On Lippert systems, the reservoir is often mounted on the pump itself.

Step 2: Check the Fluid Level

With the RV level and the slides fully retracted, remove the reservoir cap. Use a clean rag to wipe the dipstick (if equipped) or look into the tank. The fluid should be between the “Full” and “Add” marks.

If the level is low, top it off. But don’t overfill—excess fluid can cause pressure buildup and leaks.

Step 3: Add the Correct Fluid

Use only ISO 32 hydraulic fluid (or as specified by your manufacturer). Pour it slowly into the reservoir using a clean funnel to avoid spills. Wipe any drips immediately—hydraulic fluid can damage paint and rubber.

After adding fluid, replace the cap securely and run the slide in and out a few times to circulate the new fluid and purge any air.

Step 4: Inspect for Leaks

While the system is running, check hoses, fittings, and the reservoir for signs of leaks. Look for wet spots, drips, or oily residue. Even small leaks can lead to low fluid levels and system failure.

If you find a leak, tighten connections or replace damaged hoses. Never ignore a hydraulic leak—it can worsen quickly.

Pro Tips for Adding Fluid

– Always use a clean, sealed container. Never reuse old bottles that may contain dirt or moisture.

– Work in a clean area to prevent contamination.

– Label your fluid container clearly to avoid confusion later.

– Keep a spare quart of ISO 32 in your RV for emergencies.

Maintaining Your RV’s Hydraulic Slide System

Using the right fluid is just the beginning. Regular maintenance ensures your slide system stays in top condition for years to come.

Schedule Regular Inspections

Check your hydraulic system at least twice a year—before and after heavy travel seasons. Look for:

– Fluid level and condition (should be clear, not milky or dark)

– Leaks around hoses, pumps, and cylinders

– Unusual noises (grinding, whining, or knocking)

– Slow or jerky slide movement

If you notice any of these signs, address them immediately. Early detection can prevent major repairs.

Change the Fluid Periodically

While hydraulic fluid doesn’t “wear out” like engine oil, it can become contaminated over time. Dust, moisture, and metal particles can accumulate and damage internal components.

Most manufacturers recommend changing the fluid every 3–5 years or 10,000 miles, whichever comes first. If you use your RV heavily or travel in dusty environments, consider changing it more often.

To change the fluid:

1. Retract all slides fully.

2. Drain the old fluid from the reservoir (some systems have a drain plug).

3. Refill with fresh ISO 32 fluid.

4. Cycle the slides several times to purge air.

5. Check the level and top off if needed.

Keep the System Clean

Dirt is the enemy of hydraulic systems. Always keep the reservoir cap tight and the area around the pump clean. If you’re working on the system, cover open ports with clean rags to prevent debris from entering.

Also, avoid using high-pressure washers near hydraulic components. Water can force its way into seals and cause corrosion.

Lubricate Moving Parts

While the hydraulic fluid lubricates internal components, the slide’s mechanical parts—like rollers, gears, and tracks—also need attention. Use a dry lubricant like silicone spray or lithium grease to keep them moving smoothly.

Avoid oil-based lubricants on rubber seals, as they can cause swelling and leaks.

Troubleshooting Common Hydraulic Slide Issues

Even with proper fluid and maintenance, problems can arise. Here’s how to diagnose and fix the most common issues.

Slide Won’t Extend or Retract

Possible causes:

– Low fluid: Check the reservoir and top off if needed.

– Air in the system: Cycle the slide several times to purge air bubbles.

– Faulty pump or motor: Listen for humming without movement—this may indicate a failing pump.

– Blocked or kinked hose: Inspect hoses for damage or obstructions.

Slide Moves Slowly or Jerks

This is often a sign of air in the system or low fluid. Try cycling the slide multiple times. If the problem persists, check for leaks or contaminated fluid.

Fluid Leaks

Common leak points include hose connections, cylinder seals, and the reservoir cap. Tighten loose fittings and replace damaged seals. If the cylinder itself is leaking, it may need professional repair.

Unusual Noises

Grinding or whining sounds may indicate a failing pump or low fluid. Shut off the system immediately and inspect.

Conclusion: Keep Your Slides Smooth with the Right Fluid

Choosing the right hydraulic fluid for RV slides isn’t just about following the manual—it’s about protecting your investment and ensuring safe, reliable operation. By using ISO 32 hydraulic fluid (or as specified), maintaining proper levels, and inspecting your system regularly, you’ll avoid most common problems and enjoy trouble-free slide-outs for years.

Remember, your RV’s hydraulic system is a precision machine. It deserves the right care and the right fluid. Don’t cut corners with substitutes or skip maintenance. A little attention now can save you from a big headache later.

Whether you’re parked at a scenic overlook or setting up camp in a remote forest, you want your slides to work flawlessly. With this guide, you’re equipped to make smart decisions about hydraulic fluid and keep your RV running smoothly on every adventure.

Frequently Asked Questions

Can I use ATF in my RV slide system?

No, you should not use automatic transmission fluid (ATF) in RV slide systems. ATF is formulated for transmissions and can damage seals, cause foaming, and reduce lubrication in hydraulic slide systems. Always use the manufacturer-recommended fluid, typically ISO 32 hydraulic fluid.

How often should I check the hydraulic fluid level?

Check the hydraulic fluid level at least twice a year—before and after heavy travel seasons. Also inspect it whenever you notice slow or jerky slide movement, or if you suspect a leak.

What happens if I use the wrong hydraulic fluid?

Using the wrong fluid can cause seal damage, poor lubrication, foaming, and system overheating. Over time, this can lead to leaks, pump failure, or complete slide malfunction. Always follow your RV manufacturer’s recommendations.

Can I mix different types of hydraulic fluid?

No, you should never mix different types or brands of hydraulic fluid unless explicitly approved by the manufacturer. Mixing fluids can alter viscosity, reduce performance, and damage system components.

Is synthetic hydraulic fluid better for RV slides?

Synthetic hydraulic fluids offer better performance in extreme temperatures and last longer than conventional oils. They’re a good choice if you frequently travel in very hot or cold climates, but they’re more expensive. Make sure the synthetic fluid meets ISO 32 or 46 specifications.

How do I know if my hydraulic fluid is contaminated?

Contaminated fluid may appear dark, milky, or contain particles. If the fluid looks dirty or smells burnt, it’s time to change it. Contamination can clog valves and damage pumps, so regular fluid changes are important.

At CarLegit, we believe information should be clear, factual, and genuinely helpful. That’s why every guide, review, and update on our website is created with care, research, and a strong focus on user experience.