Building a car is a complex process that can take anywhere from 18 months to over 5 years, depending on the stage you’re measuring. From initial concept to final assembly, each phase—design, engineering, testing, and manufacturing—plays a critical role in shaping the timeline.

In This Article

- 1 Key Takeaways

- 2 📑 Table of Contents

- 3 How Long Does It Take to Build a Car?

- 4 The Full Lifecycle: From Idea to Road

- 5 The Production Process: From Factory Floor to Finished Vehicle

- 6 Factors That Affect Build Time

- 7 Real-World Examples: How Long It Takes to Build Popular Cars

- 8 Conclusion: A Journey of Time, Talent, and Technology

- 9 Frequently Asked Questions

- 9.1 How long does it take to assemble a car on the factory line?

- 9.2 Why does it take years to develop a new car?

- 9.3 Do electric cars take longer to build than gasoline cars?

- 9.4 Can supply chain issues delay car production?

- 9.5 How long does it take to build a custom luxury car?

- 9.6 Are robots faster than humans at building cars?

Key Takeaways

- Design and development take 2–5 years: This includes styling, engineering, and safety testing before production begins.

- Actual assembly takes 18–35 hours per vehicle: Once on the production line, a car moves through stations quickly, with final assembly completed in under two days.

- Prototype and testing phases are time-intensive: Engineers build and crash-test multiple prototypes to meet safety and performance standards.

- Supply chain delays can extend timelines: Shortages of chips, steel, or labor can slow down production significantly.

- Electric vehicles may take longer to develop: New battery tech and software systems add complexity to the design process.

- Custom or low-volume cars take much longer: Hand-built luxury or performance vehicles can require weeks or months per unit.

- Automation speeds up assembly but not design: Robots handle repetitive tasks, but human creativity and decision-making still dominate early stages.

📑 Table of Contents

How Long Does It Take to Build a Car?

So, you’re curious about how long it takes to build a car? It’s a great question—and the answer isn’t as simple as you might think. If you’re picturing a factory worker slapping parts together like a giant IKEA project, you’re only seeing the tip of the iceberg. The truth is, building a car is a massive, multi-stage process that blends art, engineering, logistics, and technology. And depending on what part of the process you’re looking at, the timeline can range from a single day to several years.

Let’s break it down. When people ask, “How long does it take to build a car?” they’re often thinking about the final assembly—the part where the engine goes in, the wheels are attached, and the car rolls off the line. That part? It can take less than a day. But if you zoom out and consider everything from the first sketch to the moment the car hits the dealership, we’re talking about a journey that can stretch across half a decade. Whether you’re a car enthusiast, a potential buyer, or just someone fascinated by how things are made, understanding this timeline gives you a whole new appreciation for the machines we drive every day.

The Full Lifecycle: From Idea to Road

Visual guide about How Long Does It Take to Build a Car

Image source: thecarhow.com

To truly grasp how long it takes to build a car, you need to look at the entire lifecycle—not just the factory floor. This journey begins long before any metal is cut or welded. It starts in the minds of designers and engineers, who spend years dreaming up, refining, and testing a new vehicle. This phase is often called the “pre-production” stage, and it’s where the foundation of every car is laid.

Imagine a team of stylists sketching futuristic shapes, engineers running simulations on crash safety, and software developers coding infotainment systems. All of this happens before a single prototype is built. And even then, those prototypes go through rigorous testing—on tracks, in wind tunnels, and in extreme climates—to make sure they’re safe, reliable, and fun to drive. Only after all that does the car move into mass production. So while the physical act of assembling a car might take a day, the intellectual and logistical work behind it takes years.

The Design Phase: Where It All Begins

The design phase is where the car’s personality is born. It usually kicks off 3 to 5 years before the vehicle hits showrooms. It starts with market research—automakers study what customers want, what competitors are doing, and what trends are emerging. Are SUVs still hot? Is there demand for electric crossovers? These insights shape the direction of the new model.

Next comes the styling. Designers create sketches and digital models, often working in clay to sculpt full-scale prototypes. These models are evaluated not just for looks, but for aerodynamics, visibility, and manufacturability. A car might look stunning in a rendering, but if it can’t be built efficiently or doesn’t meet safety standards, it’s back to the drawing board.

Once the exterior and interior designs are approved, engineers take over. They work on everything from the chassis and suspension to the electrical systems and software. This is where the car goes from a pretty picture to a functional machine. Engineers use computer-aided design (CAD) software to model every component, simulate performance, and identify potential flaws. This phase alone can take 18 to 30 months, depending on the complexity of the vehicle.

Engineering and Prototyping: Turning Ideas into Reality

After the design is locked in, it’s time to build prototypes. These aren’t just show cars—they’re fully functional vehicles used for testing and validation. Automakers typically build dozens, sometimes hundreds, of prototypes for a single model. Some are used for crash testing, others for durability trials, and some for real-world driving in extreme conditions like deserts or Arctic tundras.

Each prototype goes through a grueling checklist. Engineers test how the car handles at high speeds, how the brakes perform under stress, and how the cabin holds up to noise and vibration. They also evaluate fuel efficiency, emissions, and software performance. If something fails—say, a suspension component cracks after 100,000 simulated miles—the design team has to go back and fix it.

This phase is critical because it’s where safety and reliability are proven. For example, Tesla spent years refining the battery and software systems for the Model 3 before launching mass production. Even minor flaws can lead to recalls or reputational damage, so automakers leave nothing to chance. All told, the engineering and prototyping phase can take 12 to 24 months.

Testing and Validation: Ensuring Safety and Quality

Testing is where the rubber meets the road—literally. Once prototypes are built, they’re subjected to a battery of tests designed to mimic real-world conditions. This includes crash tests, where vehicles are slammed into barriers at various angles to assess occupant protection. These tests must meet strict government standards, like those set by the National Highway Traffic Safety Administration (NHTSA) in the U.S. or the European New Car Assessment Programme (Euro NCAP).

But it’s not just about crashes. Cars are also tested for durability, climate resistance, and long-term reliability. Some prototypes are driven millions of simulated miles on test tracks or in climate chambers that replicate everything from desert heat to Arctic cold. Others are submerged in water to check for leaks or exposed to salt spray to test corrosion resistance.

Software testing is equally important, especially for modern cars packed with sensors, cameras, and infotainment systems. Automakers run thousands of hours of diagnostics to ensure everything works seamlessly. For electric vehicles, battery performance and charging systems are tested under extreme conditions to prevent overheating or failure.

All this testing takes time—typically 6 to 12 months—and can’t be rushed. Skipping steps here could lead to dangerous flaws or costly recalls down the line.

The Production Process: From Factory Floor to Finished Vehicle

Visual guide about How Long Does It Take to Build a Car

Image source: spassio.com

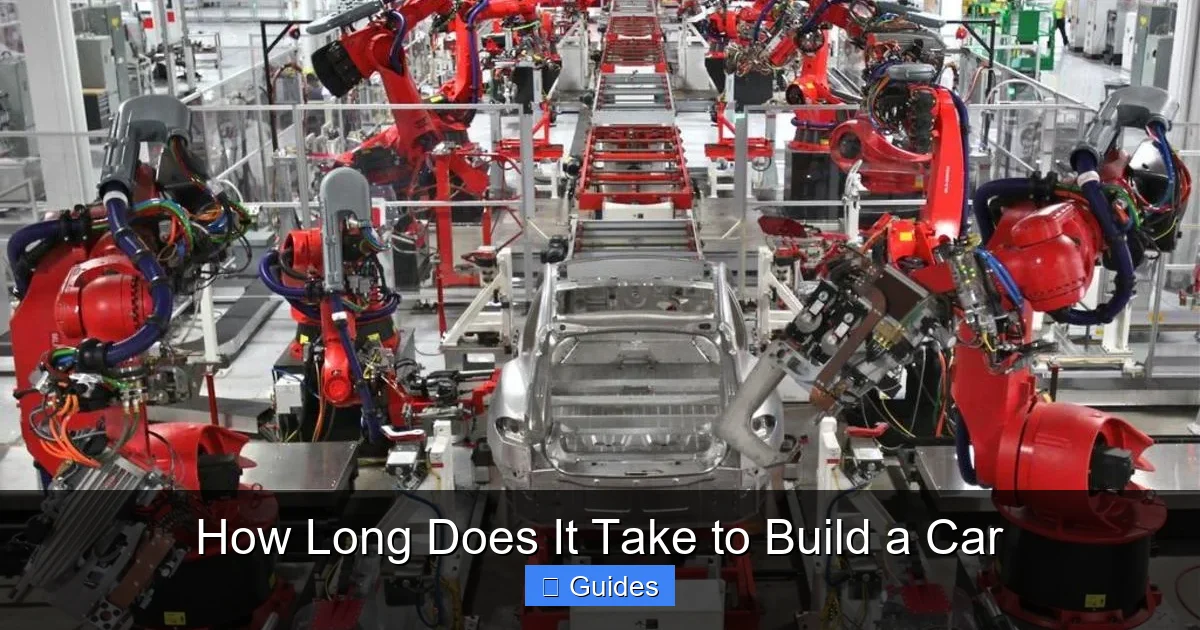

Once a car passes all tests and receives regulatory approval, it’s finally ready for production. This is the phase most people think of when they ask, “How long does it take to build a car?” And the answer might surprise you: on the factory floor, it takes just 18 to 35 hours to assemble a single vehicle.

That’s right—less than two days from start to finish. But don’t let the speed fool you. Modern car factories are marvels of efficiency, with highly automated assembly lines that move vehicles through dozens of stations in a carefully choreographed dance. Each station adds a specific component—engine, transmission, suspension, interior panels—until the car is complete.

Stamping and Welding: Shaping the Body

The production process begins in the stamping plant, where massive presses shape sheets of steel or aluminum into body panels—doors, hoods, fenders, and roofs. These panels are then sent to the welding shop, where robots use precision lasers and spot welds to fuse them together into a complete body shell, also known as the “body-in-white.”

This stage is highly automated. A single robot can perform hundreds of welds per minute, ensuring consistency and strength. The body-in-white is then inspected for defects before moving to the next stage. This entire process—stamping and welding—takes about 4 to 6 hours.

Painting: Protection and Style

Next, the body goes to the paint shop. This is one of the most complex and time-consuming parts of the assembly process. The car undergoes multiple stages: cleaning, priming, base coating, and clear coating. Each layer must dry and cure properly to ensure a durable, glossy finish.

Robots apply the paint with precision, but human inspectors still check for flaws like drips, scratches, or uneven coverage. Some luxury brands even offer custom paint jobs, which can add extra time. The painting process typically takes 8 to 12 hours, including drying time.

Final Assembly: Putting It All Together

Once painted, the body moves to the final assembly line. This is where the engine, transmission, suspension, wheels, and interior components are installed. Workers and robots work side by side, installing everything from seats and dashboards to wiring harnesses and airbags.

The engine and transmission are often pre-assembled and lowered into the chassis from below. Then, the interior is fitted—seats, steering wheel, infotainment system, and trim pieces. Finally, the wheels are mounted, fluids are added, and the car is powered up for the first time.

This stage takes about 6 to 10 hours, depending on the model and level of automation. Once complete, the car undergoes a final inspection and test drive to ensure everything works correctly.

Quality Control and Delivery

Before a car leaves the factory, it goes through a rigorous quality control check. Technicians inspect every system—brakes, lights, electronics, and more—and perform a short test drive. Any issues are corrected on the spot.

Once approved, the car is loaded onto a truck or train and shipped to dealerships. From factory to showroom, this can take anywhere from a few days to several weeks, depending on location and logistics.

Factors That Affect Build Time

Visual guide about How Long Does It Take to Build a Car

Image source: cdn.mos.cms.futurecdn.net

While the assembly process is fast, several factors can influence how long it takes to build a car—from start to finish. Understanding these can help explain why some models take longer to develop or why certain cars are delayed.

Vehicle Type and Complexity

Not all cars are created equal. A simple compact car like the Toyota Corolla can be developed and built faster than a high-performance electric SUV like the Rivian R1S. The more complex the vehicle—especially with advanced tech, hybrid systems, or custom features—the longer it takes to design, test, and produce.

Electric vehicles (EVs), for example, require new battery technology, charging systems, and software integration. These elements add layers of complexity that can extend development timelines by months or even years.

Supply Chain and Material Availability

The global supply chain plays a huge role in production speed. Shortages of critical components—like semiconductors, steel, or rare earth metals—can bring assembly lines to a halt. The 2021–2023 chip shortage, for instance, caused major delays across the auto industry, with some manufacturers idling plants for weeks.

Even minor parts, like sensors or wiring harnesses, can cause bottlenecks if suppliers can’t keep up. Automakers often rely on just-in-time manufacturing, which means parts arrive exactly when needed. Any disruption can ripple through the entire process.

Labor and Automation

Labor availability also affects build time. Skilled workers are needed for tasks that robots can’t handle—like wiring, interior fitting, and quality inspection. In regions with labor shortages, production can slow down.

On the flip side, automation speeds up repetitive tasks. Modern factories use thousands of robots for welding, painting, and assembly. While this increases efficiency, it also requires significant upfront investment and maintenance.

Regulatory and Safety Standards

Every country has its own safety and emissions standards, and cars must be certified before they can be sold. Meeting these requirements adds time to the development process. For example, a car designed for the U.S. market must pass NHTSA crash tests, while European models must meet Euro NCAP standards.

Electric vehicles face additional scrutiny around battery safety and charging infrastructure. Regulatory approval can take months, especially for new technologies.

Customization and Low-Volume Production

If you’re buying a mass-produced car like a Honda Civic, it’s built on a high-speed assembly line with thousands of units per month. But if you’re ordering a custom Bentley or a limited-edition Ferrari, the process is entirely different.

These vehicles are often hand-built or assembled in small batches, with extensive customization options. A customer might choose unique paint, leather, or trim, which requires special ordering and assembly. As a result, build time can stretch from weeks to months.

Real-World Examples: How Long It Takes to Build Popular Cars

To put things in perspective, let’s look at how long it takes to build some well-known vehicles—from concept to customer.

Toyota Corolla: The Efficiency Champion

The Toyota Corolla is one of the most efficient production cars in the world. Toyota’s lean manufacturing system allows them to build a Corolla in about 18 hours on the assembly line. From design to launch, the process takes around 3 years, thanks to Toyota’s extensive use of shared platforms and proven engineering.

Tesla Model 3: Speed Meets Innovation

Tesla aimed to revolutionize car manufacturing with the Model 3. The company claimed it could build a car in just 10 hours, but early production faced delays due to automation challenges and supply issues. Today, Tesla has streamlined the process, with assembly taking around 20–25 hours. However, the development phase took nearly 5 years, as Tesla worked to perfect battery tech and software.

Rolls-Royce Phantom: Crafted by Hand

At the other end of the spectrum is the Rolls-Royce Phantom. This luxury sedan is hand-built at the Goodwood plant in England, with each car taking over 200 hours to complete. Customers can customize nearly every detail, from paint to interior trim, which extends the timeline even further. From order to delivery, it can take 3 to 6 months.

Ford F-150: America’s Best-Selling Truck

The Ford F-150 is built on a high-volume assembly line, with production times around 24 hours per truck. Ford uses advanced robotics and modular design to speed up the process. However, the development of the aluminum-bodied F-150 took over 4 years, as engineers had to rethink everything from corrosion resistance to repair costs.

Conclusion: A Journey of Time, Talent, and Technology

So, how long does it take to build a car? The short answer: it depends. If you’re talking about the time from the first sketch to the final sale, you’re looking at 2 to 5 years. If you’re focused on the factory assembly, it’s less than two days. And if you’re ordering a custom luxury vehicle, it could be several months.

What’s clear is that building a car is a monumental effort involving thousands of people, cutting-edge technology, and meticulous planning. Every vehicle—whether a humble hatchback or a high-tech EV—is the result of years of innovation, testing, and refinement. The next time you sit behind the wheel, take a moment to appreciate the journey that brought it to you. It’s not just a machine. It’s a masterpiece of modern engineering.

Frequently Asked Questions

How long does it take to assemble a car on the factory line?

On average, it takes 18 to 35 hours to assemble a car on the factory line. This includes stamping, welding, painting, and final assembly. The exact time varies by manufacturer and vehicle complexity.

Why does it take years to develop a new car?

Developing a new car takes years because it involves design, engineering, prototyping, testing, and regulatory approval. Each phase requires extensive research and validation to ensure safety, performance, and reliability.

Do electric cars take longer to build than gasoline cars?

Electric cars often take longer to develop due to new battery technology, software systems, and charging infrastructure. However, once in production, assembly times are similar to traditional vehicles.

Can supply chain issues delay car production?

Yes, shortages of chips, steel, or other components can significantly delay production. The 2021–2023 semiconductor shortage caused major slowdowns across the auto industry.

How long does it take to build a custom luxury car?

Custom luxury cars like Rolls-Royce or Bentley can take 3 to 6 months or more to build, depending on the level of personalization and hand-crafted details.

Are robots faster than humans at building cars?

Robots excel at repetitive tasks like welding and painting, making those stages faster and more consistent. However, humans are still needed for complex assembly, quality control, and customization.

At CarLegit, we believe information should be clear, factual, and genuinely helpful. That’s why every guide, review, and update on our website is created with care, research, and a strong focus on user experience.